Surface protection of aluminum profiles

FEAL offers superior surface protection for aluminum profiles, sheets and other aluminum parts, ensuring durability, corrosion resistance and aesthetic appeal.

ELECTROSTATIC POWDER COATING

ANODISING

DECORATION (imitation of wood, stone)

With an annual capacity of over 30,000 tons, our plants guarantee the highest processing quality.

in accordance with international standards Qualicoat, Qualanod, Qualideco and GSB.

Electrostatic powder coating – perfect color and longevity

It is carried out on four automatic drives and one robotic line, ensuring uniform color, high resistance and precision of application.

- Pre-processing

creating a protective layer for better adhesion and resistance to atmospheric influences

- Electrostatic painting

- Roast

Baking the powder at 180 °C in a polymerization oven ensures the strength and resistance of the color

- Industrial robots with 6 axes enable precise powder application, even in hard-to-reach places, ensuring top quality and long-lasting paint.

- Possibility of coloring in a wide range of colors: Feal color chart, RAL colors, powders with special effects.

Materials and processing

- Length: up to 7,100 mm

- Height: up to 2,200 mm

- Width: up to 300 mm

Anodization – the process of electrochemical creation of a protective oxide layer on aluminum

Anodizing is a process of electrochemical creation of a protective oxide layer on aluminum, and FEAL owns it two automated anodizing linesWe are the holder of the quality certificate of the Qualanod organization.

which is dedicated to maintaining and promoting the quality of anodized aluminum.

- Advantages of anodizing

- High resistance to corrosion and weather conditions

- Color durability and easy maintenance

- Aesthetic appeal – matte or decorative finish

- Possibility of anodizing in different shades

- Natural aluminum color

- Bronze shades – from light to completely black

- Gold color

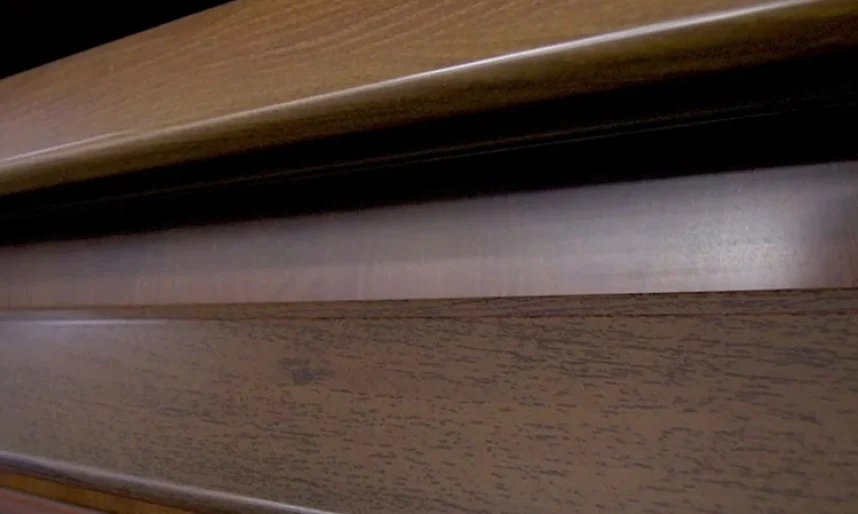

Decoration – decorative surfaces in imitation of wood and stone

With the decoration line, we have unlimited possibilities for decorating the surface of the profile in imitation of wood, stone and other decorative patterns. The process of protecting aluminum profiles takes place in two phases.

- Plasticization

- The first phase involves plasticizing the profile with polyurethane powders for protection and preparation of the surface for decoration.

- Sublimation

- The second stage is sublimation, i.e. the process of transferring the decorative pattern from the foil to the previously plasticized surface of the profile.

- The finish is certified according to Qualideco standards, which is part of the Qualicoat label for special aluminum finishes.